Yao Zhao

I am a Professor in Supply Chain Management at Rutgers Business School, and the co-director of Supply Chain Analytics Lab @ Rutgers. I hold a Ph.D. degree in Industrial Engineering and Management Sciences in 2002 from Northwestern University.

My research interests lie in supply chain management, analytics and healthcare. I published on leading operations research and management journals such as Operations Research, Manufacturing and Service Operations Management (M&SOM), Production and Operations Management, etc., as well as healthcare journals, such as International Journal of Radiation Oncology, Biology, Physics, and Personalized Medicine. I served as an associate editor for Operations Research and MSOM.

I was invited to speak at seminars of universities and industry research laboratories, such as Columbia DRO, MIT ORC, Chicago Booth, Northwestern IEMS, Stanford MSE, Michigan Ross, Maryland Smith and IBM Watson. My research was reported by media such as The European Business Review, Aviation Week and Space Technology, International Innovation, and Pharmaceutical Executives. My PhD graduates hold tenured (tenure-track) faculty positions in research universities such as the University of Delaware, the College of William and Mary, and NJIT, as well as quantitative research positions in JP Morgan and Goldman Sachs.

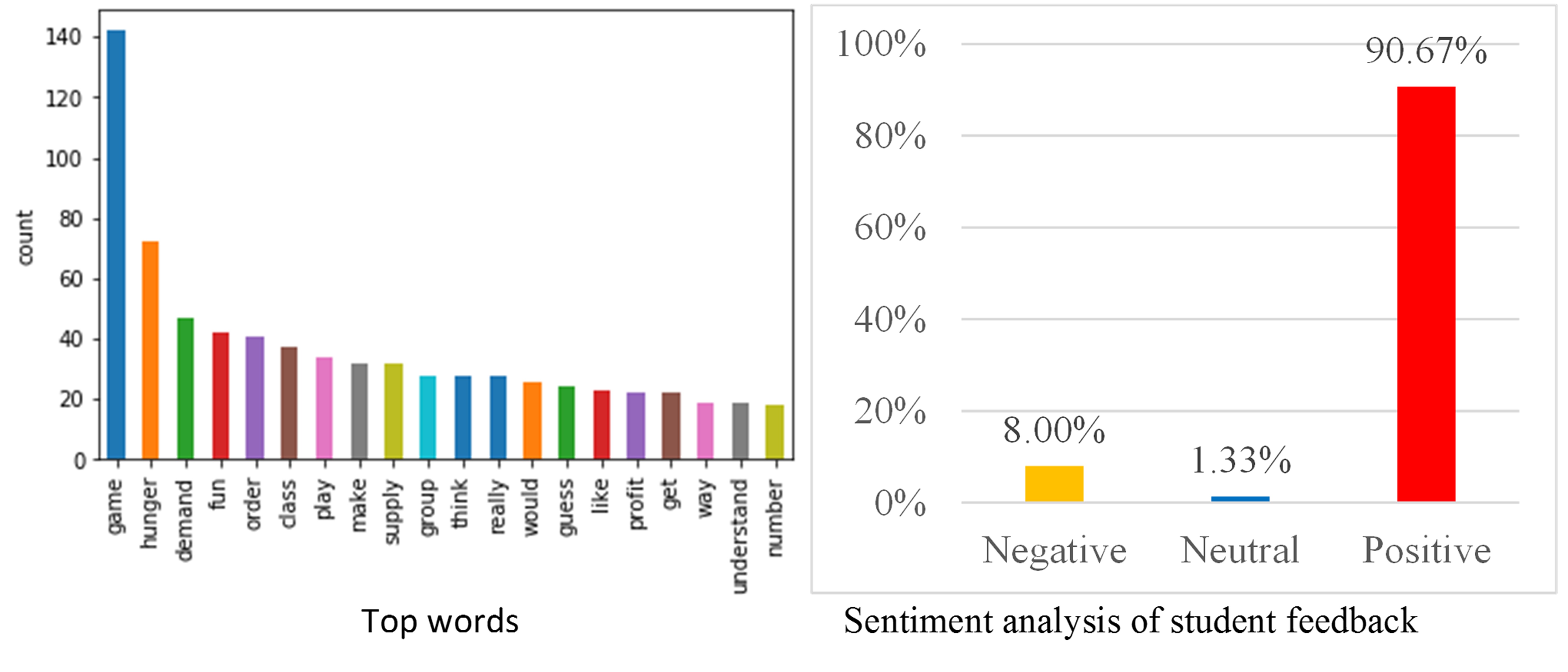

I taught core operations, supply chain and analytics courses at Rutgers Business School. I also launched a few popular MOOCs on Coursera towards the Supply Chain Analytics Specialization. Modules of my book "Supply Chain Analytics: Cases, Games and Solutions" were adopted by many supply chain management, operations management and analytics programs around the world.

I consulted with companies and government agencies, such as General Motors, Estee Lauder, Verizon, MTA – NY Transit, Special Olympics, Johnson and Johnson, Fannie Mae, Defense Logistics Agency and US Navy, Korean Air-Cargo, Robert Wood Johnson hospitals, and Water and Power Development Authority of Pakistan.

My MIT System Design Management webinar on 787 Dreamliner (12/2013) attracted a world-wide attendance of 307 people from 29 countries and 50+ companies or organizations. Our work on Special Olympics shuttle system helped the 2014 USA Games (5000 athelets, 1000 coaches and 11 locations in a 40-mile radius in NJ) to achieve 100% customer satisfaction in transportation with a budget of $600,000. Our work on Pakistan energy crisis proves the ineffectiveness of the government’s then policy and suggests an alternative, which was partially adopted with a significant economic and social impact.